Most Popular Binding Options for Print Projects

Books and promotional marketing items come in a variety of styles. Just like any other promotional product or branded material, it’s important to consider your options and how you will be using your printed piece before deciding on the type of binding you should use. Binding options have different functions. What you choose for your next print project can impact the user’s experience and even your sales. Generally, we will put most printed pieces together in one of these five ways.

Saddle Stitching

One of the most popular binding options we see our clients use is saddle stitching. Saddle stitching, or as we call it, “stitching,” is the most basic type of binding your project can use. Simply put, saddle stitching combines your pages with staples. As a rule of thumb, we use saddle stitching on most print projects with less than 100 pages. Not only is it the most affordable option, but it is also perfect for smaller run projects or temporary pieces.

2023 Update: With our newest digital machine, we can produce a “faux” perfect binding from a saddle stitch book. It takes the binding and creates a square binding instead of a rounded one. This can be done at no extra cost and comes right off our digital machine just as a saddle stitch book would.

Advantages:

- Most cost-effective binding option on digital machines.

- Used most commonly for booklets, newsletters, and mailers.

- Great for smaller print projects, books will lay mostly flat with a professional look.

- Faster turnaround time than other options as it can come straight off the printer pre-bound instead of going through a bindery process.

Disadvantages:

- Can usually only use saddle stitch when the project is less than 100 pages and must be in page increments of 4.

- Cannot print on the spine of the project.

Perfect Bound

Your project may be too large for saddle stitching or you want a nice clean, polished look to your printed piece. In this case, we usually encourage our clients to use perfect bound binding. Perfect binding is the most common soft cover binding method out there. You probably see perfect binding every day of your life; this is what is used for paperback books. With this method, the pages and cover are glued together on the spine. The covers and pages are then trimmed to give that “perfect” look and feel to them.

2023 Update: Colortech’s newest digital machine can give a “faux” perfect binding from a saddle stitch book. It takes the stitching and creates a square edge instead of a rounded one. This can be done at no extra cost and comes right off our digital machine just as a saddle stitch book would. However, you cannot print on the spine of the book with this method.

Advantages:

- Perfect binding is less expensive than hard-cover binding.

- Allows a flat, spine to be printed on.

- Can hold a larger number amount of pages than saddle stitching.

Disadvantages:

- More expensive than saddle stitching.

- Longer turnaround time.

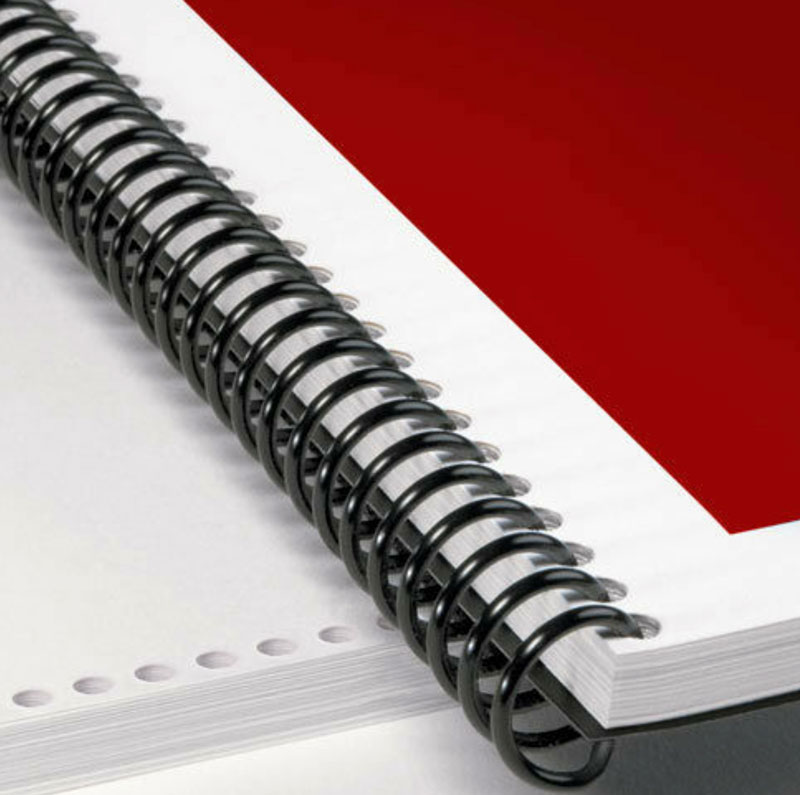

Wire-O Bound

If saddle stitching and perfect bound are not the right binding options for your print project, wire-o binding may be the best fit for you. Wire-o binding is a great option for employee handbooks and cookbooks.

The beauty of wire-o is you can lay it flat when open. Wire-o binding is created by punching holes through the collated sheets and using formed wire to connect the pages.

Advantages:

- Open the books 360 degrees while remaining flat.

- Easy to write on and hold.

- Can accommodate both small and large page counts.

- Works well with indexed sections.

Disadvantages:

- You can lose page real estate as we need about .5” of space from the inside edge to ensure the wire-o does not impede upon any text.

- No printable spine.

Spiral Binding

Very similar to wire-o binding is spiral binding or coil binding. The printer puts together spiral bounding in an almost identical fashion to the wire-o binding method. The key difference between spiral and wire-o binding is spiral binding uses plastic instead of metal wire and is in a plastic corkscrew pattern. One downside is the binding can slide out whereas the wire-o cannot.

Advantages:

- Flexible plastic coils make spiral binding a great option for mailing.

- More color options than wire-o.

- Durable material allows for pages to flow freely.

Disadvantages:

- Less professional looking than wire-o binding.

BONUS! Stepped Sheets

This is not a type of binding but a binding substitute or a replacement for single sheets.

Stepped sheets allow you to have several sheets together without incurring additional costs for binding and allow for easy, cost-effective updates and reprints. This method does not require any special die cuts, making it a great choice for organizations with multiple sheets inside a folder. Easily replace, update or customize these sheets for your needs.

Advantages:

- Easily swap, update, or customize packets without entire reprints.

- No additional die-cutting or binding costs are associated.

Disadvantages:

- No binding so papers are loose within folders.

- Harder to store and keep organized.